Tips for handling shrinkage in denim garment sizes

Tips for handling shrinkage in denim garment sizes

Today I will do the following discussion:

shrinkage

garment sizes

Clothing made of denim fabric has been loved by people for its roughness, boldness and dashing. In order to achieve denim fabric desizing, shrinkage prevention, plus soft, dehairing and garment special feel and visual effect, garment washing has become one of the characteristics of denim clothing. Industrial mass production, clothing garment size and through the clothing paper sample size to reflect the specific, coupled with denim clothing in the production process of pulling cloth, cutting, small ironing, sewing, washing, finishing and other different process requirements of the impact, will be on the clothing garment size to produce a certain amount of accumulation of deformation, affecting the clothing garment size and processing quality.

Denim is woven with color yarn color woven fabric, is derived from the United States in 1873, German immigrants Levi Strauss, sewed into jeans, and reinforced with copper rivets, to fully meet the requirements of the then western United States gold miners and put the cowboys on the solid wear-resistant clothes and pants, initially, mostly jeans, and then gradually formed a series of popular around the world, and has become one of the most popular casual clothing varieties in the international market today. The most popular leisure clothing varieties in today’s international market. With the development of the times, denim clothing from the past varieties of single color, the development of varieties of styles, color changes, new production processes are endless.

Then how to deal with denim fabric shrinkage in the paper size and process production links in a variety of impact on the size of the garment, it is worth exploring the denim industry.

1、 Fabric shrinkage affects garment size

As we know, after weaving, cutting, production and other multi-process processing of denim clothing, generally according to market or customer demand, using special water grinding, stone grinding, snow, rinsing, sand washing, acid washing and other washing and finishing. In order to achieve denim fabric desizing, shrinkage prevention, plus soft, dehairing and garment special feel and visual effect. Different washing methods will directly or indirectly affect the garment size, so the fabric shrinkage is the main factor affecting the garment size. So the shrinkage rate of fabric is the main factor that affects the garment size. This makes it necessary for us to fully consider the shrinkage rate of fabric when making paper samples.

2, the fabric yarn to affect the garment size

In the same fabric, the same style, the same garment size requirements, when a part or the whole fabric yarn selection is different, if the fabric shrinkage rate is larger, and we use the same fabric shrinkage rate to calculate, it will bring a certain deviation to the size of the garment, affecting the shape of the garment, difficult to meet the customer’s requirements.

3、Sewing edge, folding edge thickness affects garment size

Test denim fabric shrinkage rate, usually in a piece of plane denim fabric, and some sewing edge or folding edge and other parts of the thickness increase, garment washing, these thickening of the sewing edge, folding edge can not be even with it parts of the shrinkage rate, it will be on the effect of the garment and the size of the garment to bring the impact.

The main factors of denim clothing fabric shrinkage

fabrics in addition to cotton, pure silk, there are elastic (spandex), hemp cotton, polyester cotton, rayon, etc.; in the weaving process, in addition to twill, there are also plain, milled, bamboo yarn, jacquard, etc.; in terms of thickness can be divided into 4.5 an, 6 an, 8 an, 10 an, 11 an, 12 an, 13.5 an, 14.5 an and so on.

Due to the raw materials used in denim fabrics, weaving process, fabric specifications, yarn thickness and density of different sizes, coupled with the fabric fiber’s own hygrothermal properties, will produce shrinkage effect before and after the production of garments, affecting the garment’s ready-to-wear size and processing quality. In fact, the main cause of shrinkage of denim fabrics are natural shrinkage, heat shrinkage, shrinkage in water (shrinkage) and other three cases.

1、Natural shrinkage factors

Natural shrinkage refers to the shrinkage phenomenon of fabrics from the factory to use before. Due to denim fabrics in the weaving, processing, fiber by a certain degree of mechanical external force, and make the fiber, yarn and fabric elongation, resulting in leaving the potential strain, as well as the type of fabric fibers, weaving process, storage conditions and time, etc., will produce a certain degree of accumulation of deformation, affecting the degree of natural contraction of fabrics. Some denim fabrics natural contraction may also be negative, which all give denim clothing paper size control brings certain difficulties.

2, the factor of heat shrinkage

Heat shrinkage of denim fabrics, mainly refers to denim fabrics in the production of ironing, ironing process contraction phenomenon, due to the denim fabric fiber thermoplastic and fabric pulling performance factors, in the ironing, ironing process temperature is too high will produce contraction phenomenon, affecting the size of the garment.

3, shrinkage in water (shrinkage) factors

Denim fabric fiber water absorption will produce anisotropic expansion effect, the warp and weft yarn curvature increases, the fabric becomes thicker, the size of the shortening, is the main reason for fabric shrinkage in water absorption, this shrinkage is also called shrinkage. Generally speaking, the better the hygroscopicity of the fiber used in the fabric, the greater the shrinkage of the fabric itself, and vice versa. Ordinary denim will have a 2%-3% horizontal and vertical shrinkage rate, while stretch denim can shrink up to 10% or more.

Enterprises dealing with denim fabric shrinkage andCommonly used method of clothing paper sample size

Clothing enterprises in the denim clothing paper pattern division in the production of paper samples, need to consider a lot of factors, different customer requirements, different elastic denim (containing spandex, shrinkage rate of up to 10% or more), different sewing process and washing requirements, version of the size should be adjusted accordingly. At present, the methods used by the enterprise paper pattern makers, some of them are more scientific and practical, worth popularizing, some of them have some deficiencies and need to be improved.

1, will denim fabric pre-shrinkage and then cut production

In the production of denim clothing paper samples, in addition to modeling the effect of style to carefully review, but also consider the performance of the selected fabrics and shrinkage rate. Before making clothes, denim weaving factory after finishing workshop, generally have to denim fabric for a pre-shrinkage and shaping treatment, so as to make the denim fabric size stability is guaranteed. Some production enterprises will choose to completely release the cloth, let the fabric in a natural state placed in a certain period of time, and then bed cutting, this pre-shrinkage way, can also play a role in stabilizing the size of the cost is not big, it is worth promoting.

There are also some enterprises will denim fabric first wash treatment, and then cut production, this way although can stabilize the size of the garment, but it is difficult to present the special garment washing effect of denim clothing.

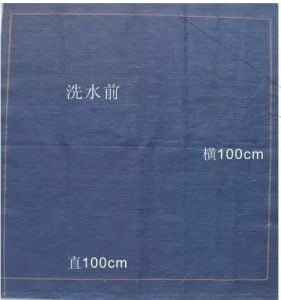

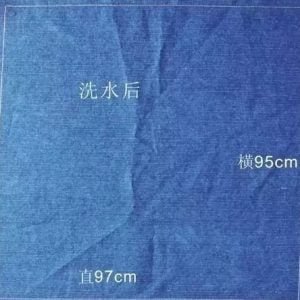

2, based on the test fabric horizontal, straight shrinkage, in the paper sample size plus put the amount of shrinkage below to introduce the enterprise test fabric shrinkage method, take pre-production denim a piece of fabric, draw a horizontal × straight (100cm × 100cm) of the box and seized line.

Then according to the garment washing standard washing (must be the same washing standard with the future garment washing). After washing and finishing, the box size is measured again. Shrinkage rate can be calculated. See the data in

Then according to the garment size and shrinkage rate, calculate the paper size. For example: hip circumference to cut across the grain (5%), customers require garment size 100cm, then the paper sample size should be 100 ÷ (1-5%) = 105.27cm, (because the hip circumference before washing is 105.27cm, the size of the wash is 105.27 × (1-5%) = 100cm, just the size of the customer’s requirements of the garment). The above calculations, it seems reasonable, but this method only takes into account the impact of fabric shrinkage, but not consider the choice of fabric pattern, sewing edge folding thickness and process and other aspects of the impact of the garment size stability can not be guaranteed.

3, in the apparel CAD system to deal with the size of paper samples plus put shrinkage

Manual production of paper samples, each part of the size of a separate calculation, time-consuming and laborious, while the CAD system can be calculated as a whole, quickly reflect the obvious advantages. Currently apparel CAD system to solve the paper sample size plus put the amount of fabric shrinkage method has two kinds.

(1) in the apparel CAD sample system will be the sample as a whole put the amount of shrinkage

In the CAD sample design system, the first does not take into account the shrinkage of the fabric, the sample will be made, and then in the “Cutting Attribute Definition” dialog box, “Initial Shrinkage” input box, directly enter the fabric’s horizontal yarn shrinkage rate of 5%, the straight yarn shrinkage rate of 3%, the system will automatically take the “horizontal yarn sample” as the “initial shrinkage” input box. Automatically to “horizontal yarn sample size ÷ (1-5%)” and “straight yarn sample size ÷ (1-3%)” for accurate calculations, the sample of the horizontal and straight direction of the calculation, and the overall amount of shrinkage put.

(2) in the clothing CAD scheduling system will mark the overall amount of reserved shrinkage

In the CAD scheduling system, “bed properties” dialog box, warp and weft direction shrinkage input box, directly enter the straight yarn fabric shrinkage rate of 3%, 5% shrinkage rate of horizontal yarn, and then enter the width of the fabric in the width of the door width of 110cm, the system is automatically to “estimate the length of the mark frame × (1 – 3%) “and” width 110 × (1-5%) = 104.5cm ”for the calculation of the bed mark frame for the overall reduction, in this way to reserve the amount of shrinkage. Then in the paper sample system, there is no need to put the sample for shrinkage processing. Will not be put on the shrinkage of the sample, in a good amount of shrinkage reserved for the mark on the row material. Printing and drawing, the system can be the whole bed mark frame to width “104.5 ÷ (1-5%)” and “warp length ÷ (1-3%)” for the calculation, and the whole bed mark frame stretch printing, so that the print out of the samples of the mark frame has been the whole plus put the horizontal and vertical shrinkage. Straight shrinkage amount.

Discharge system is the whole of the mark frame horizontal, straight direction of the amount of shrinkage reserved, the same method can not take into account the sewing edge folding thickness and the production process and other aspects of the impact on the size of the garment, you need to rely on the experience of the paper modeler to adjust the data, can not ensure that the size of the garment is stable.

Comprehensive approach to denim garment size shrinkage

In industrial mass production of denim garments, due to the many variables affecting the garment size, the size shrinkage of each part of the denim garment is not uniform, therefore, it is necessary to pay attention to and control each production process from the beginning to the end. In order to ensure the stability of denim garment size, the paper sample size, in addition to considering the amount of fabric shrinkage, must also be considered throughout the manufacturing production process, including fabric pulling, cutting, small ironing, sewing, sewing, finishing, measuring methods and other process standards. If these factors are considered separately, and in the paper samples to add or subtract adjustments to deal with, often lose sight of the other. I think that since the garment size reflects the impact of each process, then these effects can be synthesized in the paper sample in one step. Below, a pair of jeans paper sample production as an example to illustrate.

1, targeted test denim garment sample parts shrinkage rate

First of all, in accordance with the customer’s requirements of the garment size and process requirements, the production of a base code jeans paper samples do not take into account the shrinkage. Secondly, in order to further reflect the sample production process and the consistency of high-volume assembly process, do not arrange special cut board, car board, but according to the customer’s requirements, follow the custom of the enterprise production process, by the workshop assembly line production of a sample pants, see (Fig. 09) before the wash, and finally, washing and finishing to meet the customer’s standards, see (Fig. 10) after the wash. At this time, according to the requirements of the sample jeans parts measured shrinkage rate, the relevant data see

It should be noted that, when doing sample pants, it is best to do several at a time, measured several sample pants site shrinkage rate after taking the average value, so that the data obtained.

Due to the workload and technical obstacles when manually placing sizes, the problem of the shrinkage rate of the specification stall size has been ignored by the industry, but when the number of yards is large and the shrinkage rate of the fabric is large, placing sizes without considering the amount of shrinkage of the stall size will also lead to instability of the garment size. If the clothing CAD system “garment size specification table” dialog box, can be designed to add a group of fill in the parts of the shrinkage rate of the options, and programmed by the system to calculate the paper samples plus put the amount of shrinkage after the size, then in the release of the code at the same time, but also be able to synchronize to solve the specification of the difference between the size of the stalls and put the amount of shrinkage problem.